Page 13 - Manufacturing Engineering Brochure 2023 WEB

P. 13

Smart Factory AU4956 AUTOMATICS

AUTOMATICS

The Automatics Smart Factory allows students to get the experience of a number

of processes and technologies commonly used in manufacturing and modern-day

industry 4.0 principles. This includes conveyor systems, sensing systems, pneumatic SMART FACTORY

pick and place technology, DC motor drivers and stepper motor drivers. The factory

includes coloured discs made from plastic and other materials. A conveyor belt

moves these pieces into the factory, where user programmed sensors sort the discs

SMART FACTORY

into multiple rejection bins. Some are picked off the conveyor by a suction device

and a stepper motor controlled gantry sorts the discs into appropriately coloured

containers. The smart factory can be used with Siemens (or other brand) 12V or 24V

PLC. ROBOT ARM

ROBOT ARM

Robot Arm Integration

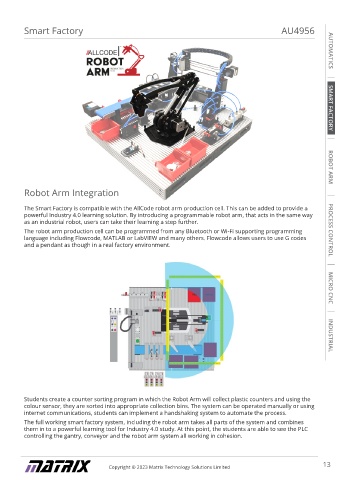

The Smart Factory is compatible with the AllCode robot arm production cell. This can be added to provide a

powerful Industry 4.0 learning solution. By introducing a programmable robot arm, that acts in the same way

as an industrial robot, users can take their learning a step further.

The robot arm production cell can be programmed from any Bluetooth or Wi-Fi supporting programming PROCESS CONTROL

language including Flowcode, MATLAB or LabVIEW and many others. Flowcode allows users to use G codes

and a pendant as though in a real factory environment. MICRO CNC

PROCESS CONTROL

MICRO CNC

INDUSTRIAL

Students create a counter sorting program in which the Robot Arm will collect plastic counters and using the INDUSTRIAL

colour sensor, they are sorted into appropriate collection bins. The system can be operated manually or using

internet communications, students can implement a handshaking system to automate the process.

The full working smart factory system, including the robot arm takes all parts of the system and combines

them in to a powerful learning tool for Industry 4.0 study. At this point, the students are able to see the PLC

controlling the gantry, conveyor and the robot arm system all working in cohesion.

12 Copyright © 2023 Matrix Technology Solutions Limited Copyright © 2023 Matrix Technology Solutions Limited 13