Page 17 - Manufacturing Engineering Brochure 2023 WEB

P. 17

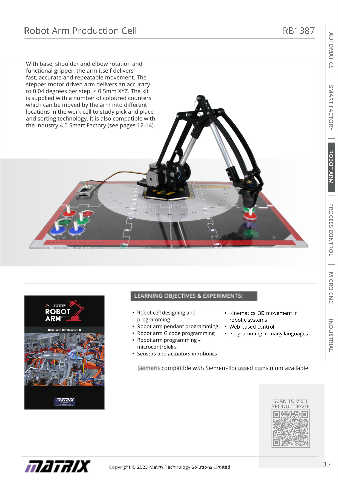

Robot Arm Production Cell RB1387

With base, shoulder and elbow rotation and AUTOMATICS

functional gripper, the arm itself delivers

AUTOMATICS

fast, accurate and repeatable movement. The

stepper motor driven arm delivers an accuracy

to 0.04 degrees per step, < 0.5mm XYZ. The kit

is supplied with a number of coloured counters

which can be moved by the arm into different SMART FACTORY

locations in the work cell to study pick and place

Robot Arm and sorting technology. It is also compatible with

the Industry 4.0 Smart Factory (see pages 12-14).

The robot arm production cell consists of a rugged

SMART FACTORY

stepper motor controlled 3 degrees of freedom arm

bolted to a base plate and supplied with an activity

mat that provides a range of exercises to replicate

an industrial robot arm. The free instructional guide

includes worksheets in pendant, G code, API and ROBOT ARM

microcontroller programming, sensors and actuators,

kinematics and more. The user can connect the robot

ROBOT ARM

arm production cell to their hardware platform –

Windows PC, Android mobile, Raspberry Pi/Linux device

using USB, Bluetooth or Wi-Fi technology.

Multiple Programming PROCESS CONTROL

Methods

Users of the robot arm can program from many

programming IDE’s Including Flowcode, App

PROCESS CONTROL

Inventor, C++/ VB / C#, Python, LabVIEW or

their own industrial PLC. This is made possible

through the publication of an API (Application

Programming Interface), which consists of a MICRO CNC

library of commands which make programming LEARNING OBJECTIVES & EXPERIMENTS:

via USB, Bluetooth or Wi-Fi possible from

multiple software sources.

MICRO CNC

• Robot cell designing and • Kinematics: 3D movement in

programming robotic systems

• Robot arm pendant programming • Web based control

• Robot arm G code programming • Programming in many languages INDUSTRIAL

• Robot arm programming –

microcontrolelrs

• Sensors and actuators in robotics

INDUSTRIAL

Siemens compatible with Siemens focussed curriculum available

SCAN TO VISIT

PRODUCT PAGE

Refined Design

The mechanics of the arm are designed to maximise the payload (the amount the arm can lift). This is

achieved by placing the heavy motors on the base platform and by using a system of levers and cogs to allow

the arm to move with great precision within its range of motion.

16 Copyright © 2023 Matrix Technology Solutions Limited Copyright © 2023 Matrix Technology Solutions Limited 17